- Home

-

Docs

- DeepLog

- App manual

- DeepLog Portal

- Hardware manual

- Portal

- WE110

- Manual for thermostat and generic control

- Manual for gate opener

- Application notes

- Downloads

- WE111

- Web Interface manual

- 1. General information

- 2. Variables management

- 3. Events/Actions

- 4. Scheduler

- 5. Variables monitoring

- 6. Data delivery

- 7. Users

- 8. Connectivity

- 9. System commands

- 10. Diagnostic

- 11. System operations

- 12. Safety guidelines

- 13. Warranty and support

- 14. Return and repair

- Web Interface manual

- WE112

- Web Interface manual

- 1. General information

- 2. Variables management

- 3. Events/Actions

- 4. Scheduler

- 5. Variables monitoring

- 6. Data delivery

- 7. Users

- 8. Connectivity

- 9. System commands

- 10. Diagnostic

- 11. System operations

- 12. Safety guidelines

- 13. Warranty and support

- 14. Return and repair

- Web Interface manual

- WE120

- Quick start guide

- Connecting the WE120 to a computer

- Firmware update

- User manual

- Commands manual

- Genesys 3

- Application notes

- Reference cases

- Downloads

- FAQ

- WE151

- Web Interface manual

- 1. General information

- 2. Variables management

- 3. Modbus

- 4. Events/Actions

- 5. Scheduler

- 6. Variables monitoring

- 7. Data delivery

- 8. Users

- 9. Connectivity

- 10. System commands

- 11. Diagnostic

- 12. System operations

- 13. Safety guidelines

- 14. Warranty and support

- 15. Return and repair

- Web Interface manual

- WE152

- Web Interface manual

- 1. General information

- 2. Variables management

- 3. Modbus

- 4. Events/Actions

- 5. Scheduler

- 6. Variables monitoring

- 7. Data delivery

- 8. Users

- 9. Connectivity

- 10. System commands

- 11. Diagnostic

- 12. System operations

- 13. Safety guidelines

- 14. Warranty and support

- 15. Return and repair

- Web Interface manual

- WE200

- Quick start guide

- Software Manual

- Hardware manual

- Application notes

- QuickTunnel

- Downloads

- WE300

- Quick start guide

- Hardware manual

- Software manual

- 1. General information

- 2. Variables

- 3. Modbus

- 4. Events/Actions

- 5. Scheduler

- 6. Variables monitoring

- 7. Data sending

- 8. Datalogger

- 9. Users

- 10. Settings

- 11. Commands

- 12. Diagnostic

- 13. System operation

- 14. Safety guidelines

- 15. Warranty and support

- 16. Return and repair

- WE500

- Quick start guide

- Hardware manual

- Software Manual

- 1. General information

- 2. Variables

- 3. Modbus

- 4. Events/Actions

- 5. Scheduler

- 6. Variables monitoring

- 7. Data sending

- 8. Datalogger

- 9. Users

- 10. Connectivity

- 11. Commands

- 12. Diagnostic

- 13. System operation

- 14. Safety guidelines

- 15. Warranty and support

- 16. Return and repair

- Plugins

- Application notes

- Reference cases

- API

- FAQ

- WE500R

- Quick start guide

- Hardware manual

- Software Manual

- 1. General information

- 2. Variables

- 3. Modbus

- 4. Events/Actions

- 5. Scheduler

- 6. Variables monitoring

- 7. Data sending

- 8. Datalogger

- 9. Users

- 10. Settings

- 11. Commands

- 12. Diagnostic

- 13. System operation

- 14. Safety guidelines

- 15. Warranty and support

- 16. Return and repair

- API

- VPN

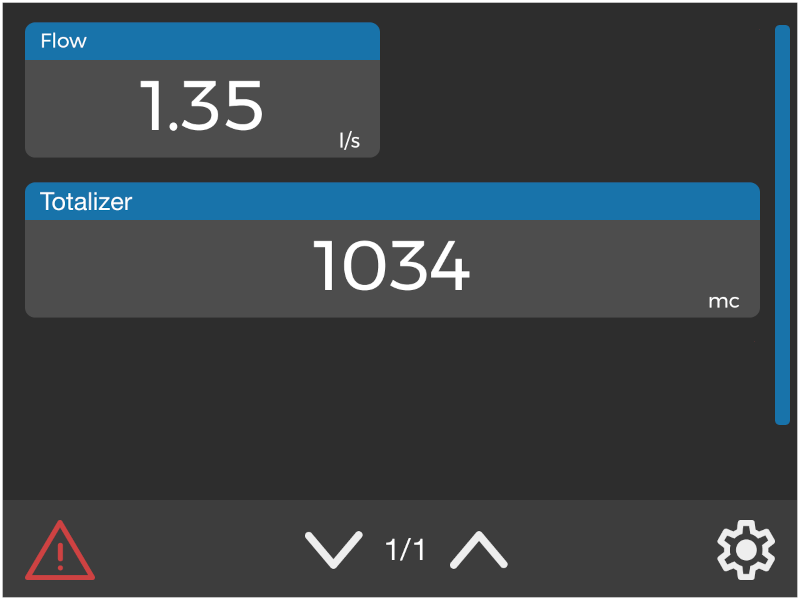

- Touch Panels

- TP100

- Power supplies

- Expansions

- XP100

- XP500

- XP500/ETH

- DIS500

- DeepLog

- Languages