2.1. The Story-Line

The client manages water installations for private companies and the government. For this project, they need to manage a water tank for a municipal entity.

Besides the water level monitoring in the tank that needs to trigger several actions when the level reaches a uses-defined threshold, the client needs to monitor the incoming and outgoing water flow allowing them to command the valves.

The valve’s management must be handled by a scheduler that allows to program automatically the valve’s opening and closing.

The client must be able to connect to the device remotely through the 2G/3G connection using a dynamic DNS provider.

2.2. The Solution’s Approach

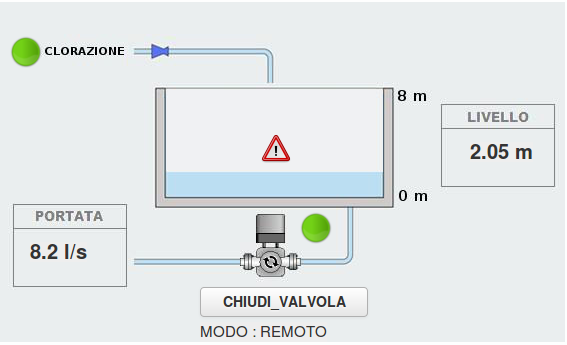

In order to monitor the system with an easy and comprehensible graphic interface that shows the water tank and its parameters, a customized schematic was developed.

This schematic contains the image of the water tank that displays the current water level. It is also dynamic, since the level sensors are read at given period of time are displayed automatically.

The schematic also displays other parameters that are monitored such as the GPRS connection status and a button that allows to open or close the valve.

Through the powerful scheduler functionality, the customer can organize when the valve must be opened or closed automatically without being physically on the site.

The scheduler can be configured with three different approaches:

- Execute based on a recurrent time. Eg. Monday, Wednesday and Friday at 8 o’clock.

- Execute every number of time units. Eg. Each hour

- Execute only once. Eg. July 1st, 2015 at 8:15

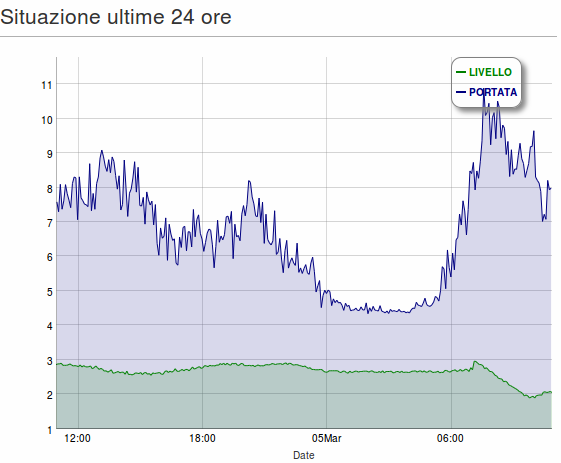

From the status page the customer can monitor in real-time the water level in the tank. He can also download reports based on a configurable date and time.

In order to make a WE500 accessible through a domain name such as watertank.we500.net, each time that the WE500 establishes a 3G data connection, it updates the dynamic DNS provider with the just acquired IP address. The customer can choose one of the several paid and free providers.