2.1. The Story-Line

The customer builds and installs small to large size PV plants. In this specific case, the PV plant contains 3 inverters, to each inverter there are 2 string boards and to each string board there are 10 strings.

This system can be extended to support up to 6 inverters, each inverter can support up to 6 string boards and each string board can support up to 24 strings. This means that this system can have up to 864 strings that translates to thousands of parameters since for each string there are at least a current, a tension and a produced power.

In order to remotely manage and monitor the inverters, string boards and strings, it needs a solution that allows to access the system from any where at any moment.

The customer also needs a secure, flexible and user-friendly interface that is available at any moment through a 2G/3G data connection.

There are some systems that allow to remotely monitor the system, but they are quite limited in the number of monitored parameters and do not provide 2G/3G connectivity.

2.2. The Solution’s Approach

Nethix’s solution allows its clients to remotely monitor each single parameter that exist in the system through a user-friendly web interface accessible using a PC, laptop or even a mobile device from a 2G/3G connection, LAN or even wireless LAN.

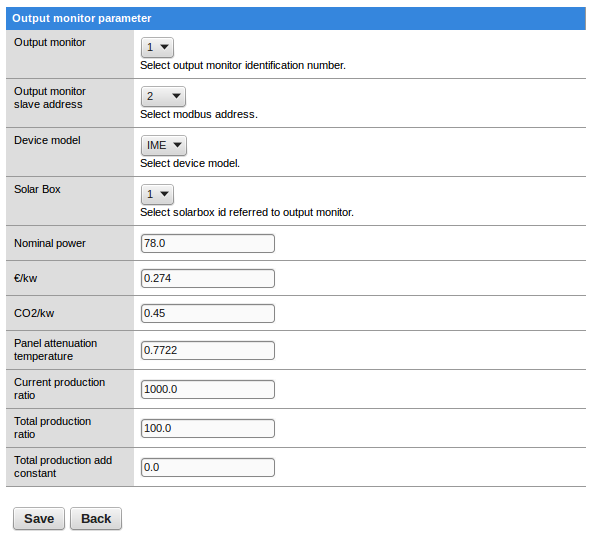

The WE500 allows to configure any aspect of the PV plant on-the-fly, without rebooting nor stopping any service, providing a continuous monitoring activity required by the client.

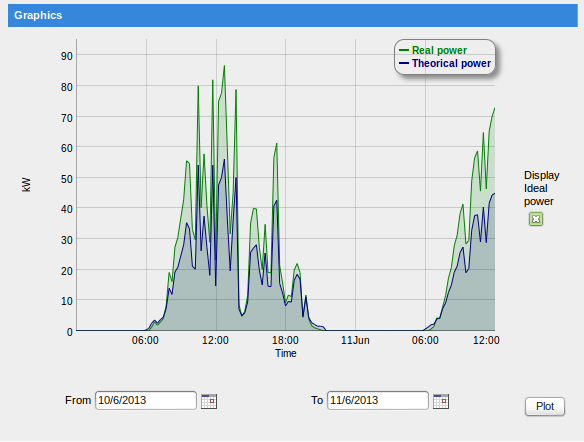

A relevant part of the monitoring tasks that is provided by this solution is to generate multi-trace graphics that are useful when analyzing the behavior of the system in a given period of time as well as send notifications to selected users when a certain condition is raised.

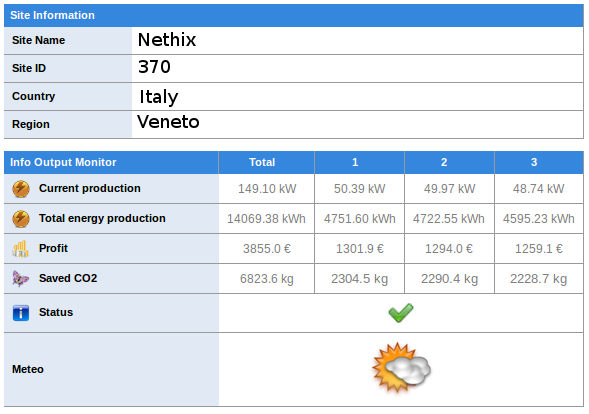

From the main screen the user can visualize at-a-glance the site information and the most important parameters of the three inverters as well as their agreggates:

By expanding the parameters monitoring screens, the system displays the three inverters (monitors) in three separated tabs. Each tab shows the most relevant real-time data for each one of the inverters such as current real/ideal power and total production as well as the production totalizers.

This is quite useful for the end-client since from here she can check the saved CO2 and profits that the system is generating.

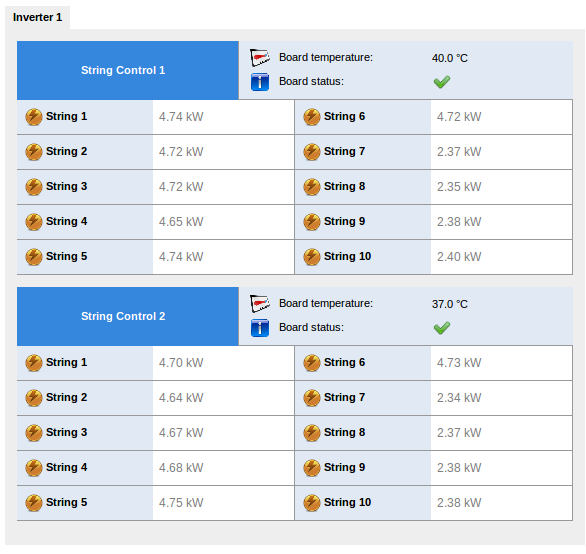

The intuitive user interface can show the real-time status of a string board as well as the power produced by each one of its strings, in this case 10 strings in each one of the 2 string boards:

One of the unique characteristics of the WE500 is that it allows to configure any aspect of the PV plant on-the-fly, without rebooting nor stopping any service. The same applies for the alarms and their actions that can be edited without altering the normal functionality of the system.

When a new inverter is added to the system, new modbus variables are created and added dynamically to the list of monitored parameters without altering other services. This can be done thanks to the multi-tasking characteristics of the WE500.

The WE500 can generate multi-trace graphics that can be quite useful when analizing the behavior of the system in a given period of time. One of the most useful comparisons are the real power vs the theoretical power.

2.3. Benefits

The first PV plants that could take advantage of the WE500 were installed in 2012 and from that time the system has had an availability of 99.9% .

The customer is quite satisfied with the reliability and flexibility that the WE500 has proved during all these years.

These are the main benefits of the WE500 solution:

- Reduces maintenance costs of the PV plant

- Provides real-time monitoring for each inverter, string board and string

- Increases customer satisfaction through reliable and long-term support